Enit Product Carbon Footprint (PCF)

Convince customers with the product carbon footprint

The smart solution for industrial companies that want to win in the market with full transparency.

Convince customers with the product carbon footprint

The smart solution for industrial companies that want to win in the market with full transparency.

Quick results with intelligent software: What options are there to make product costing easy?

Fill out the form and watch the free webcast!

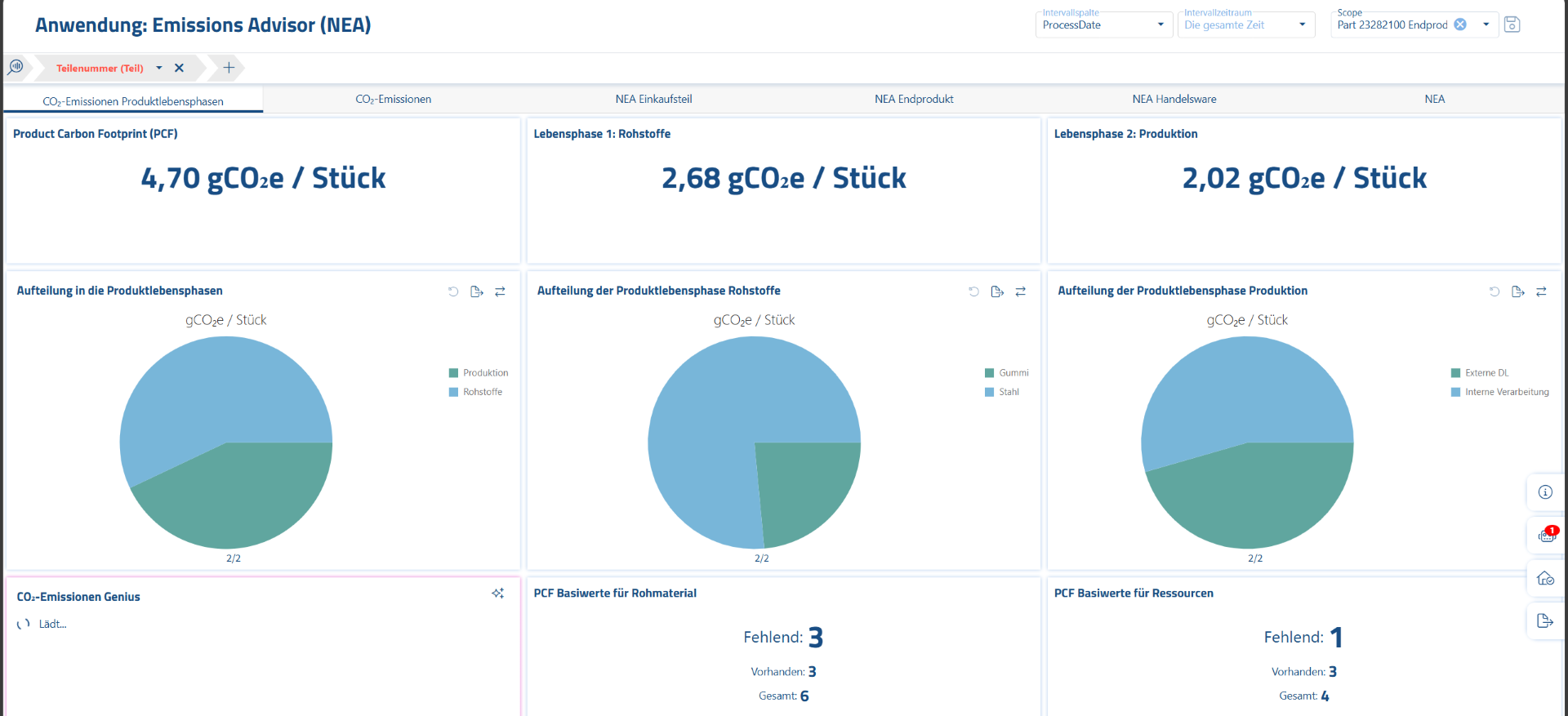

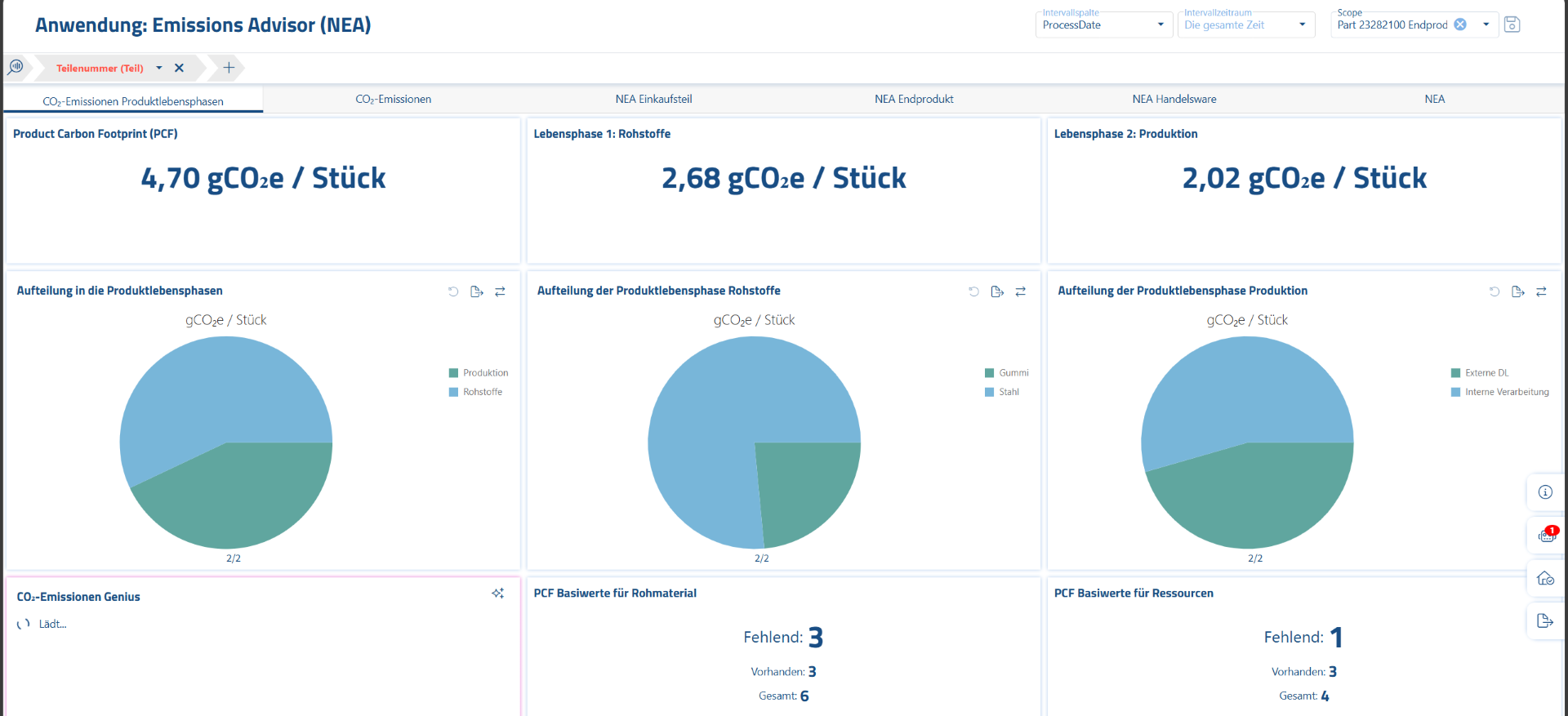

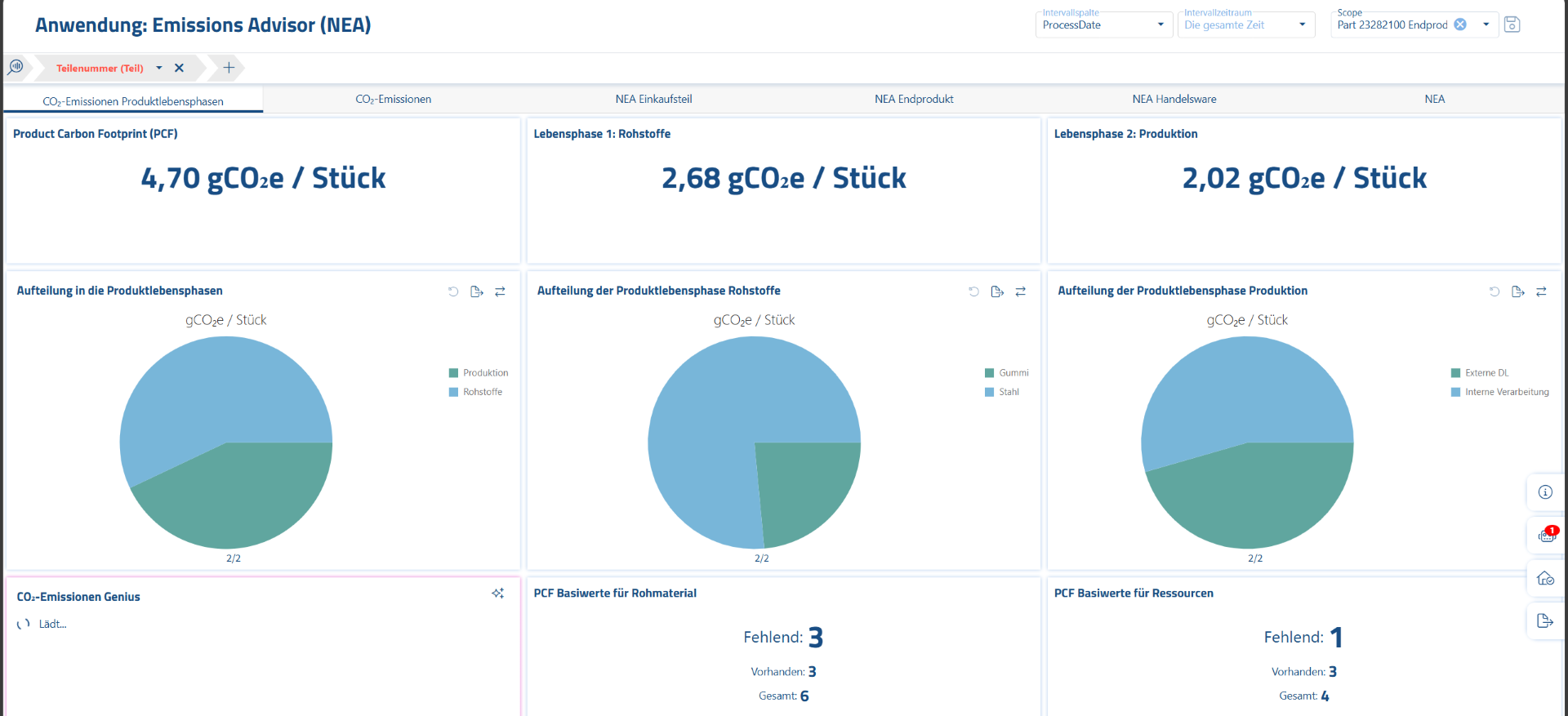

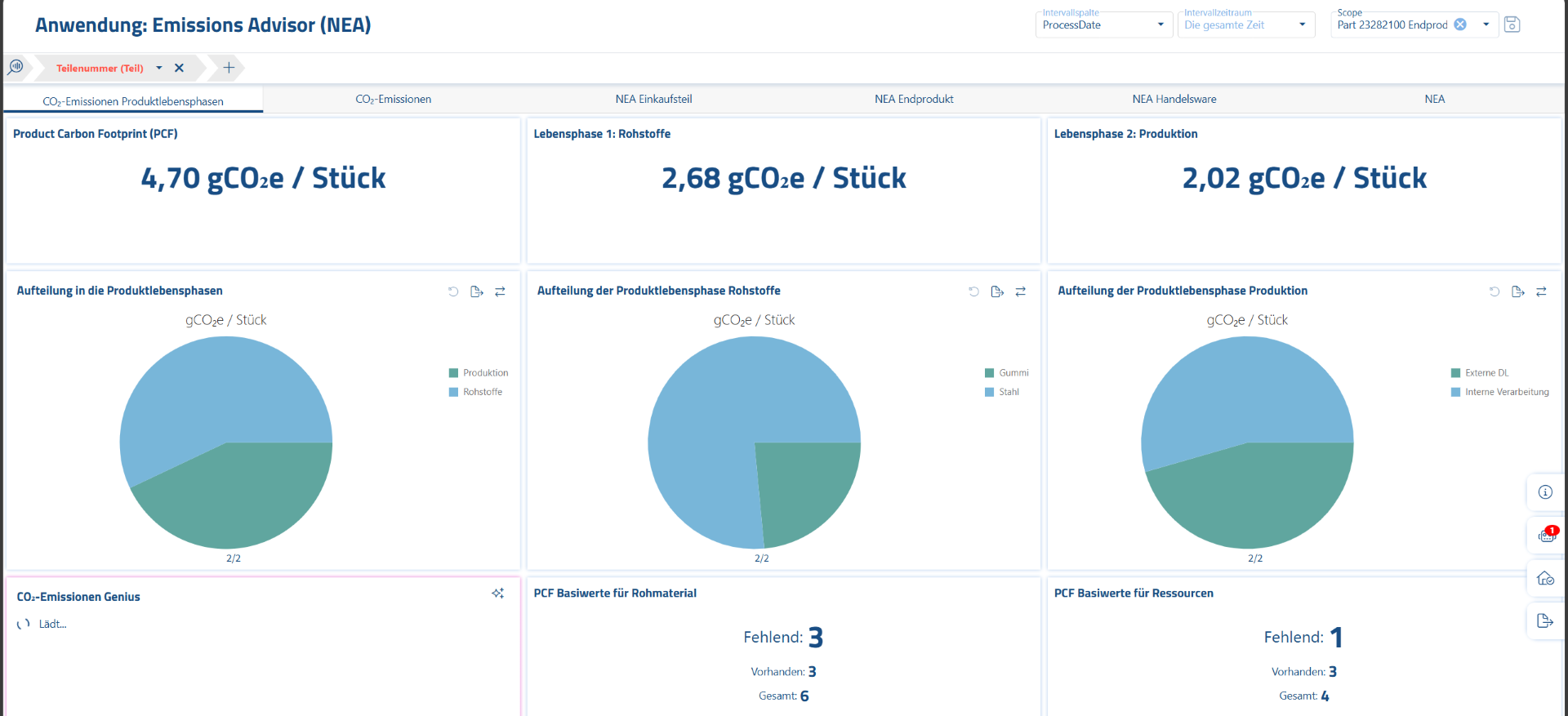

Shown here: Product emissions by life phase.

For an insight into all functions, please contact us here.

Shown here: Product emissions by life phase.

For an insight into all functions, please contact us here.

Shown here: CO2 workshop at SCHNEEWEISS interior in Kippenheim.

For an insight into all functions, please contact us here.

Shown here: CO2 workshop at SCHNEEWEISS interior in Kippenheim.

For an insight into all functions, please contact us here.

Shown here: Product emissions by life phase.

For an insight into all functions, please contact us here.

Shown here: Product emissions by life phase.

For an insight into all functions, please contact us here.

Shown here: CO2 workshop at SCHNEEWEISS interior in Kippenheim.

For an insight into all functions, please contact us here.

Shown here: CO2 workshop at SCHNEEWEISS interior in Kippenheim.

For an insight into all functions, please contact us here.

Would you like to create transparency, maintain your competitive advantage, assume social responsibility and communicate this in the best possible way with the help of a product carbon footprint?

Even if you have a complex product portfolio and individual manufacturing processes, we can help you create your PCF.

Discover our solution for your Product Carbon Footprint (PCF) - and achieve your sustainability goals!

Arrange a free info call now and calculate yourCO2 product balance!

Then let us arrange a non-binding consultation!

We look forward to showing you our PCF solution and answering your questions.

Our PCF calculation and consulting services are based on internationally recognized standards:

✔️ GHG Protocol Product Standard

✔️ ISO 14067

Are you planning to implement your PCF? We are at your side as a reliable partner - feel free to contact us.

The PCF is often better suited for communication with customers, suppliers, employees and the public than the Corporate Carbon Footprint (CCF). The reason for this is that the PCF is directly related to the product. When large corporations pursue sustainability goals, this usually means that they require suppliers to provide information on product-related emissions. A product carbon footprint thus becomes a decisive aspect in the supply chain.

According to its definition, the product carbon footprint comprises the greenhouse gas emissions along the entire life cycle and thus along the entire value chain of a product. In accordance with the GHG Protocol, the associated emissions are allocated to the following five product life cycle phases as part of a product carbon footprint:

- Raw materials

- production

- distribution

- use

- disposal

The operational system boundary is used to define which of these product life cycle phases are taken into account in the accounting. A basic distinction is made between the "cradle-to-gate" and the "cradle-to-grave" approach. If all of the five life cycle phases mentioned are included in the product accounting, the "cradle-to-grave" approach is used. If the product accounting only includes all emissions up to the boundary of the company's own factory gate and not beyond, the "cradle-to-gate" approach is used.

The consideration of all relevant aspects in the development of a cross-company calculation methodology can be approached differently depending on the use case.

Based on cost accounting, you can use Enit to develop a PCF calculation methodology using the cost of sales approach. A major advantage: although this approach requires an initial effort to develop the calculation methodology, there is no need to consider the products individually. In the following, we show examples of which emission sources can be included in such a calculation methodology:

With the Enit PCF, we offer you customized solutions for creating your product carbon footprint, even for complex product portfolios and individual manufacturing processes. By implementing a Nemo interface, this process can be further simplified and automated, resulting in increased transparency and efficiency in CO2 balancing.

The methodology of our product balance was checked and successfully validated by the independent auditing company GUTcertin the project with fischer Hydroforming. This gives you the security of relying on comprehensible and auditable data - whether for customer requirements, internal decisions or regulatory reports.